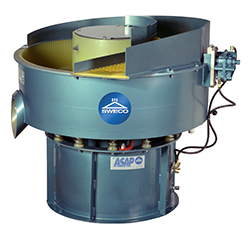

FINISHING MILLS

Time-tested technology provides three-dimensional Vibro-Energy motion for all SWECO Finishing Mills. This motion subjects parts and media to a consistent high frequency tilting movement as they travel in a helical/orbital path around the chamber. The resulting compressive scrubbing action cleans and also removes burrs, round sharp corners, and smooths out surface impressions. Because vertical/horizontal amplitudes and the rate of vibration are completely adjustable, your finishing requirements can be handled quickly and efficiently.

Batch Mills SWECO Batch Finishing Mills are ideally suited for use with external separating systems, manual parts unloading and for processes that have no media and the entire load can be easily discharged out the bottom door.

Long Radius Mills SWECO Long Radius Finishing Mills provide a convenient means for separating parts from media. The DLR series provides both batch automatic and continuous finishing. Internal parts and media separation mills utilize a swing blade and a fixed separation screen mounted within the unit. The long-radius toroidal chamber design has excellent discharge characteristics.

Spiral Mills SWECO Spiral Finishing Mills or SLR series mills make available a long-radius spiral finishing chamber featuring fully-automatic parts/media separation utilizing an air-operated discharge gate and a fixed separating screen. Even unusual shapes and sizes discharge easily. These units are suitable for a wide range of finishing applications (including ball burnishing and media finishing) both batch and continuous. One of the most essential features on these mills is the long retention time of parts for single pass applications.

Removable Center Column Mills The SWECO Removable Center Column Finishing Mill offers all the advantages of SWECO's unique Vibro-Energy finishing plus design features for easier operation and more efficiency. The chamber, which incorporates a removable center column, allows you to run larger than normal parts in the mill. Adjustments in finishing action are easily made by varying lead angle and motor weight settings. No tools are required for such adjustments. Sound levels have been reduced by the use of special materials and new fabrication techniques.

The complete spectrum of finishing from rough to delicate can be quickly and efficiently handled by this batch unit. With the proper media it will perform deburring, flash removal, edge-breaking, metal clean-up, rough surface work or preplate finishing- even radiusing or precision surface reduction. Available with 1, 3, 10, 14 and 23 cubic feet bowls.

NEWS and EVENTS

Upcoming Exhibition

GEAPS Exchange 2026 will take place February 21-24, 2026 in Kansas City, Missouri at the Kansas City Convention Center. SWECO will be displaying the Vibro-Energy HX™ Round Separator, ideal for use in grain handling and processing. Please stop by Booth 3414 to check out our offerings and speak to a SWECO professional about your application and separation requirements.

Upcoming Exhibition

CONEXPO CON/AGG 2026 will take place March 3-7, 2026 in Las Vegas, Nevada at the Las Vegas Convention Center. SWECO will be displaying the ATLAS™ Gyratory Sifter, ideal for use in mining and mineral processing. Please stop by Booth C32786 to check out our offerings and speak to a SWECO professional about your application and separation requirements.

Upcoming Exhibition

Interphex 2026 will take place April 21-23, 2026 in New York City at the Javits Convention Center. SWECO will be displaying the PharmASep™ Pharmaceutical Aseptic Filter/Dryer, designed for the aseptic batch filtration, washing and drying of pharmaceutical solids. Please stop by Booth 3403 to check out our offerings and speak to a SWECO professional about your application and separation requirements.

Upcoming Exhibition

Petfood Forum 2026 will take place April 27-29, 2026 in Kansas City, Missouri at the Kansas City Convention Center. SWECO will be displaying the Vibro-Energy HX™ Round Separator and Low Profile Flow Thru Bag Dumper Screener. Both systems are utilized in various pet food applications. Please stop by Booth 933 to check out our offerings and speak to a SWECO professional about your application and separation requirements.

Upcoming Exhibition

Pack Expo International 2026 will take place October 18-21, 2026 in Chicago, Illinois at McCormick Place. SWECO will be displaying the Vibro-Energy HX™ Round Separator and Low Profile Flow Thru Bag Dumper Screener. Both systems are ideal for use in Food & Beverage applications and prepackage processing. Please stop by Booth LU-7643 to check out our offerings and speak to a SWECO professional about your application and separation requirements.